产品详细

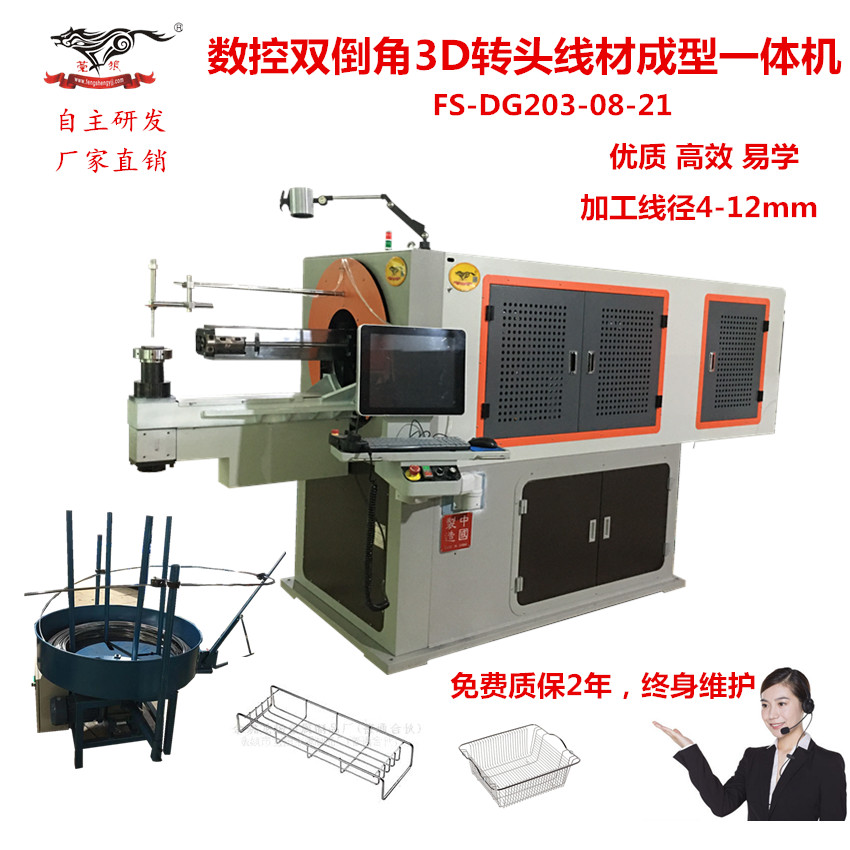

名称: 枫盛转头式3D线材成型机FS-DG203-08-5120

Fengsheng 3D wire forming

machine with bending turret FS-DG203-08-5120

品牌brand: 莞狼/枫盛(FS)

本机适合生产较大线径的金属丝,速度快,产品精准度高、容易操作和修改、数据储存量大,广泛适用于

汽车连接杆、座椅骨架等零部件和工艺品、卫厨配件、超市货架,家具座椅,园林工具等3-12mm线径配件折弯成型

本机适用于铁线、钢线、包胶线、不锈钢线及有色金属线材(圆、方、扁线),打(弯制)方、圆、六角、椭圆及

各种不规则形状的平面及立体线材形状成型。

转头机的特点是适合做大线经、杆件类金属线材的产品

This type with bending turret is designed for making thick wire, rod shaped metal wire products,etc.

简述:生产线经4-12mm。Brief description: Available processing diameter:4-12mm.

适用于:汽车连接杆、座椅骨架等零部件和工艺品、卫厨配件、超市货架,家具座椅,园林工

等4-12mm线径配件折弯成型。

Applicable to: Forming&bending wires with diameter between 4-12mm , such as automobile connecting rod, seat frame and other parts, as well as artware, sanitary and kitchenware, supermarket shelves, furniture seats, garden tools, etc.

一、枫盛转头线材成型机FS-DG203-08-5120技术参数

Technical parameters of Fengsheng 3D wire forming

machine with bending turret FS-DG203-08-5120

|

序号 |

类型type |

详细参数Detailed parameters |

|

1 |

设备型号Equipment type |

FS-DG203-08-5120 |

|

2 |

加工线经规格Processing diameter |

Φ4-Φ12mm(抗拉强度tensile strength≤500N,including Q195/Q235) |

|

3 |

控制轴数Number of control axes |

5 |

|

4 |

转臂电机功率Jib motor |

3.8KW |

|

5 |

送线电机功率Wire feeder motor |

15KW |

|

6 |

外模转动电机功率Outer mold rotor |

2.0KW |

|

7 |

升降电机功率Lifter motor |

1.0KW |

|

8 |

切刀电机功率Cutter motor |

1.0KW |

|

9 |

最大送线速度Maximum wire feeding speed |

90m/min |

|

10 |

送线精度Wire feeding accuracy |

300mm±0.3 |

|

11 |

自动送线架最大承重Maximum load of automatic wire feeder |

1500Kg |

|

12 |

自动送线架圆盘直径Diameter of automatic wire feeder’s circumcircle |

φ1900mm |

|

13 |

自动送线架电机功率Motor power of automatic wire feeder |

2.2KW |

|

14 |

主机电压Voltage of the main machine |

AC380V(±20V) |

|

15 |

主机器重量Weight of the main machine |

2800kg |

|

16 |

主机器尺寸Measurement of the main machine |

3800mm X 2000mm X 1900mm(L×W×H) |

|

17 |

自动送线架重量Weight of automatic wire feeder |

800Kg |

|

18

|

自动送线架尺寸Measurement of automatic wire feeder |

2400mmX2400mmX1750mm |

二、使用条件及说明:Operation conditions and instructions

1、 电源电流及电压1秒种以上波动应保证在±5%以内,设备可以正常运行。

2、 自动送料架与主机间隔距离2000mm以上。

3、 设备配备有USB接口,可实现数据读取。

4、 电脑操作系统可以接入互连网,实现远程控制和操作。生产效率及产量在人机界面有显示,达到规定产量后设备可自动停机。

1. The power supply current and voltage fluctuation for more than one second shall be within ± 5%, under this circumstance, the equipment can operate normally.

2. The automatic cradle and the main machine shall be at least 2000mm apart.

3. The device is equipped with USB interface for data reading.

4. The computer operating system can be connected to the Internet for remote control and operation. The production efficiency and output are displayed on the human-machine interface, and the equipment can be automatically shut down after reaching the pre-set output.

三、其它other

1、 设备使用后齿轮箱及导轨滑块要定期加润滑油脂,周期60个工作日。

2、 附易损件及配置参照表如下。

1. After the equipment is used, add lubricating grease to the gear, guide rail and slide block every 60 working days.

2. Attached vulnerable parts and configurations are as follows.

A;整机配套周边设备:Main machine and components:

|

序号 |

货品内容 Product content |

数量QTY |

单位 UNIT |

备注 Notes |

|

1 |

FS-DG203-08-5120 五轴数控线材成型机Five-shaft CNC wire forming machine |

1 |

台 set |

(包含)VAT-included |

|

2 |

自动送线架(1500kg)Automatic wire feeder (1500kg) |

1 |

台 set |

(包含)VAT-included |

|

3 |

运输及保险费(国内运输)Freight and insurance (domestic transportation) |

1 |

套 set |

(不包含)VAT-excluded |

|

4 |

配套刀具/模具 Attached cutter / mold |

2 |

套 set |

(包含)VAT-included |

|

5 |

免费提供1人培训 Free training for 1 personnel |

5 |

天 day |

(包含)VAT-included |

B;.整配件品牌及产地:Brand and origin of components:

|

配件名称 Component name |

品牌/产地 Brand / origin |

|

配件名称 Component name |

品牌产地 Brand / origin |

|

伺服电机 Servo motor |

SANYO |

|

变频器 Frequency converter |

台湾台达Taiwan taida |

|

直线滑轨 Linear slide rail |

台湾上银 Taiwan Silver |

控制系统 Control system |

莞狼控制系统 |

|

|

键盘Keyboard |

罗技Logitech |

轴承Bearing |

日本NSK |

|

|

编码器Encoder |

SANYO |

减速机Reducer |

德国纽卡特/台湾品宏Newcastle, Germany / Pinhong, Taiwan |

|

|

电源Power |

台湾明纬 Taiwan Mingwei |

机座材质 Frame material |

国标45#/A3 45#/A3 steel |

|

|

显示屏Interface |

台湾友达 Taiwan Youda |

|

|

C;.易损件随机配送清单Random distribution list of vulnerable parts:

(请勿超负荷使用Please aware the service life of each parts, best not overload.)

|

序号 |

名 称 Name |

样图 Pattern |

使用寿命Service life(year) |

备注Notes |

|

1 |

送线轮 Traction pulley |

|

≥1-2 |

模具规格根据客户产品线径大小定制The mold can be customized according to clients’ demand. |

|

2 |

小直折角柱 Small punch-pin |

|

≥1 |

|

|

3 |

折角盘3.5 Outer mold 3.5

|

|

≥2 |

小孔近距离 Small hole & short distance |

|

4 |

折角盘6.5 Outer mold 6.5

|

|

≥2 |

大孔远距离 Big hole & long distance |

|

5 |

切刀 Cutter

|

|

≥1 |

模具规格根据客户产品线径大小定制The mold can be customized according to clients’ demand. |

|

6 |

短导线板 Short conductor plate |

|

≥2 |

|

|

7 |

固定式折角头 Fixed punch-pin mate |

|

≥2 |

|

|

8 |

导向管Wire guide |

|

≥2 |